Our range of counter matrix systems are manufactured to the highest tolerance so to maximise the on-press performance and deliver consistent and high quality creasing.

They are designed to complement our range of Braille embossing systems to improve make-ready times from one Braille variance to the next whilst retaining their integrity. Lasercomb will pre-determine the most effect counter matrix specification dependant on the substrates being converted.

- LasercombPertinax Counter Matrix – Each set are individually designed to the one on profile and eliminate the need for on press handwork. Furthermore Lasercomb has the ability to pre-mount the matrix in position across a range of machine sizes from B2 (760mm) right through to Size 6 (1420mm) saving valuable on-press make-ready time.

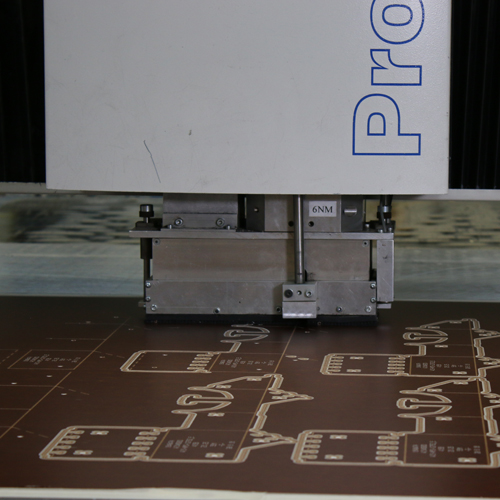

- LasercombBrass Counter Matrix – The ultimate in counter matrix; Lasercomb can manufacturer via our CNC technology brass counter matrix for the regular repeating and long running production order.

Counter Matrix are a key ingredient to Lasercomb press ready culture. From the standard durable and cost effective Pertinax counter matrix through to the CNC manufactured brass system.

Key Benefits

- Lasercomb Counter Matrix Individually designed to suit the 1on design and the substrate being converted.

- Lasercomb Counter Matrix Available in standard Pertinax material or a harder wearing 2 x2 material.

- Lasercomb Counter Matrix Designed to eliminate any on press handwork.

- Lasercomb Counter Matrix Compliment the complete Lasercomb range of Braille force systems from Fast-fit, Slide-fit and Magnetic fit.

- Lasercomb are able to pre-mount Counter matrix directly onto a thin cutting plate from B2 though to Size 6 formats saving valuable machine time.

- Lasercomb Counter Matrix offer accurate & consistent registration to the cutting die.

Technical Features

- Lasercomb Counter matrix all tailor made to achieve consistent and accurate creasing quality.

- Counter matrix are available in increments of 50 microns.

- Double sided adhesive applied as standard.

- Customised channel widths & depths to suit dependent upon substrates being converted.

- High quality chamfering program is applied to all sets.

- Available with the Fast-fit Braille system, Slide-fit Braille system & our Magnetic Braille system.

- Pre-mounted counter matrix service available on 760mm / 1020mm / 1040mm / 1420mm .