Blanking Tools

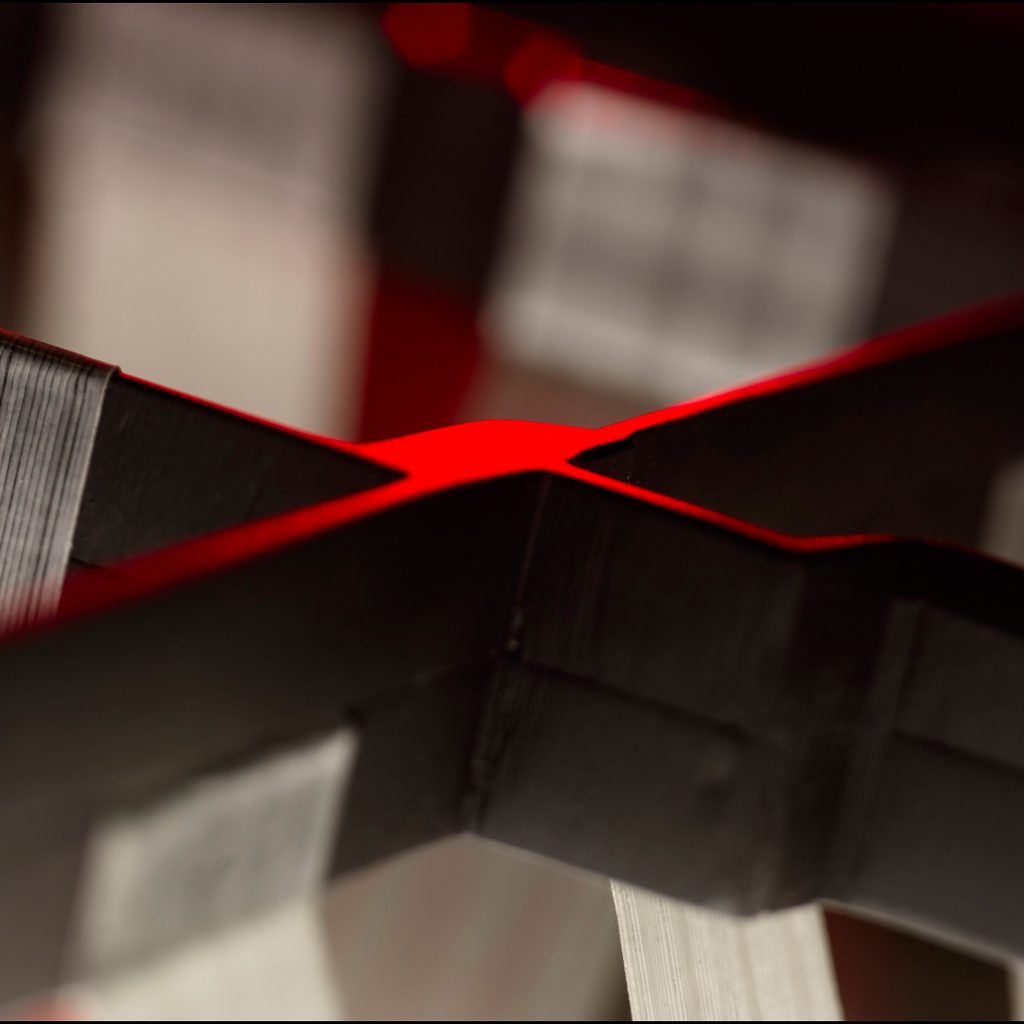

Lasercomb Dies range of blank separating systems are truly unique within the die-making industry.

Every top and bottom tool is individually designed to suit the production layout. Bespoke manufacturing enables Lasercomb blanking systems to minimise on press make ready times and maximise on press production speeds whilst delivering undamaged clean; presentable and fully separated products.

- Lasercomb Blank Separating Systems are yet more Lasercomb innovations for blanking layouts which were previously thought unsuitable for blank separating. Our design and technological development in blank separating has meant that the blanking process is now far more accessible to many more companies than before.

- Lasercomb Easy-Grid A system tailored to suit layouts that are in line or have a slight step.

- Lasercomb Laser-Grid A system tailored to suit complex double and single cut layouts where the design is turned and interlocked or contains complex waste areas.

- Lasercomb Wire-Grid A system tailored to suit single cut sleeve or card layouts

- Lasercomb Outrigger-Grid A system tailored to suit double cut sleeve layouts and very small RTE or OTE single cut layouts.

- Lasercomb Flexi-frame A revolutionary lower blanking frame system that significantly reduces the cost of blanking

- Lasercomb Light top blanker A CNC machined top tool that is light weight & operator friendly offering improved accuracy and performance

Blanking systems What ever your blank requirements Lasercomb will have a fit for purpose solution.

Key Benefits

- Lasercomb Blank Separating Systems Tailor made to each layout & die-cutter specification

- Lasercomb Blank Separating Systems Blanks layouts previously thought unsuitable to blank

- Lasercomb Blank Separating Systems Four styles of system to suit your blanking requirements

- Lasercomb Easy-Grid A system to suit layouts that are inline or have a slight step

- Lasercomb Light top blanker Improved accuracy and durability

- Lasercomb Laser-Grid A system to suit complex double and single cuts where the design is turned and interlocked or contains complex waste areas

- Lasercomb Wire-Grid A system tailored to suit single cut sleeve or card layouts

- Lasercomb Outrigger-Grid A system tailored to suit double cut sleeve layouts and very small RTE or OTE single cut layouts.

- Lasercomb Flexi-frame Designed to reduce the cost of blanking to our customers whilst retaining the vital integrity required

Technical Features

- Lasercomb Blank Separating Systems are tailor made to customers’ exact requirements

- Manufactured from the latest technology, materials innovations and design

- Lasercomb Precision manufactured for optimum blanking performance

- A range of lower frames are available to support the internal grid including our lightweight aluminium frame, dedicated steel frame and the BSI frame allowing grids to be interchanged.

- Lasercomb Easy-Grid A lightweight but durable lower blanking tool system designed for in line or slightly stepped layout blanking and fabricated from laser-cut bars

- A range of top presser bars are available to suit both long and short production runs.

- Lasercomb Laser-Grid A robust and virtually unbreakable lower blanking tool for complex double and single cut work and turn layouts laser or water-jet cut and constructed from a solid sheet of steel

- A range of lower frames are available to support the internal grid including our lightweight aluminium frame, dedicated steel frame and the BSI frame allowing grids to be interchanged.